Mitsubishi Materials Group supports perovskite evolution: Next-generation energy technology for a sustainable future

Many countries, including Japan, have set a goal of achieving carbon neutrality by 2050, and promoting the use of renewable energy is a shared global challenge. One of the technologies currently attracting the most attention is perovskite solar cells. With advantages such as light weight, flexibility, high efficiency, and low cost, perovskite solar cells are rapidly being developed both in Japan and overseas as a breakthrough alternative to conventional silicon-based solar cells.

What are perovskite solar cells?

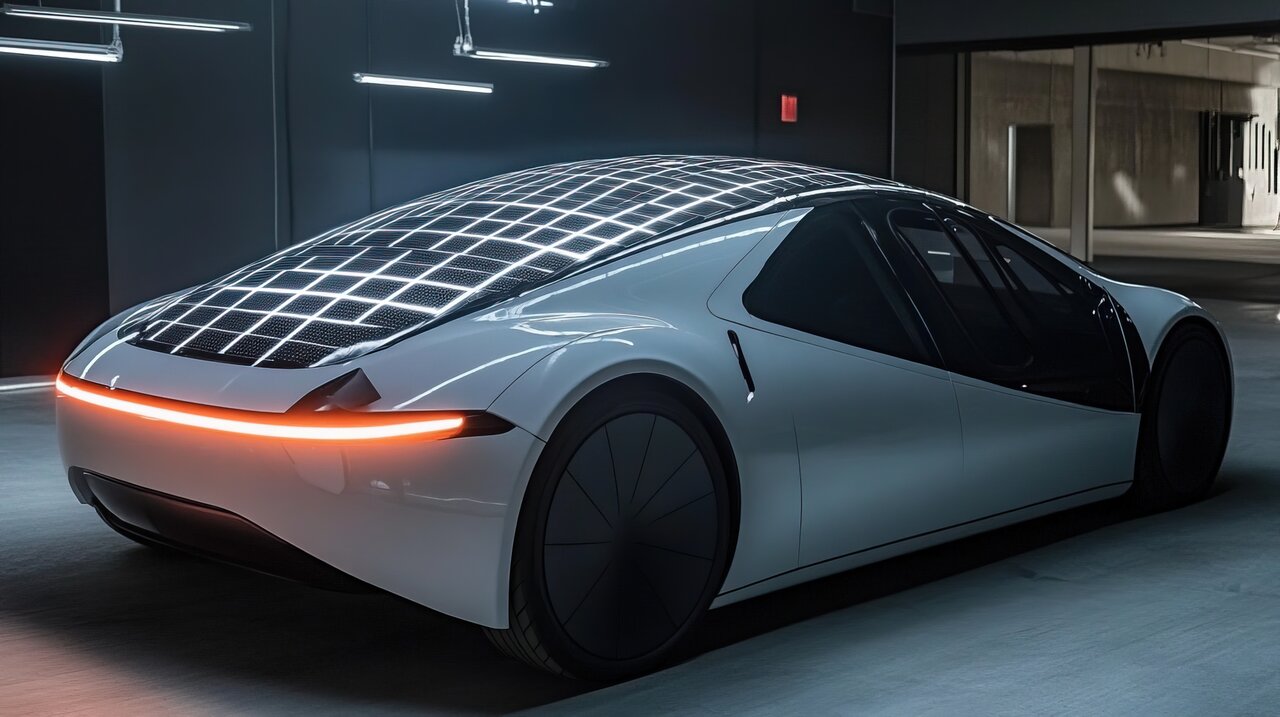

Perovskite solar cells are next-generation solar cells made with materials that have a perovskite structure. Their greatest features are their light weight and bendability. Compared to conventional silicon solar cells, they offer greater flexibility, enabling applications in previously difficult locations, such as building walls, car bodies, and wearable devices. In addition, the manufacturing process is simple, and a "coating process" using printing technology allows for low-cost mass production.

Japan is a world leader in perovskite solar cell research, leveraging its expertise in precision coating and high-performance encapsulation films. Furthermore, while China is the primary source of polysilicon, the key raw material for silicon solar cells, Japan is the world's second-largest producer of iodine, a key ingredient in perovskite solar cells, giving it an advantage in terms of raw material procurement. Energy conversion efficiency is also improving year by year, reaching a level comparable to that of silicon solar cells in the research stage, raising high expectations for future practical application and widespread adoption.

Japan is a world leader in perovskite solar cell research, leveraging its expertise in precision coating and high-performance encapsulation films. Furthermore, while China is the primary source of polysilicon, the key raw material for silicon solar cells, Japan is the world's second-largest producer of iodine, a key ingredient in perovskite solar cells, giving it an advantage in terms of raw material procurement. Energy conversion efficiency is also improving year by year, reaching a level comparable to that of silicon solar cells in the research stage, raising high expectations for future practical application and widespread adoption.

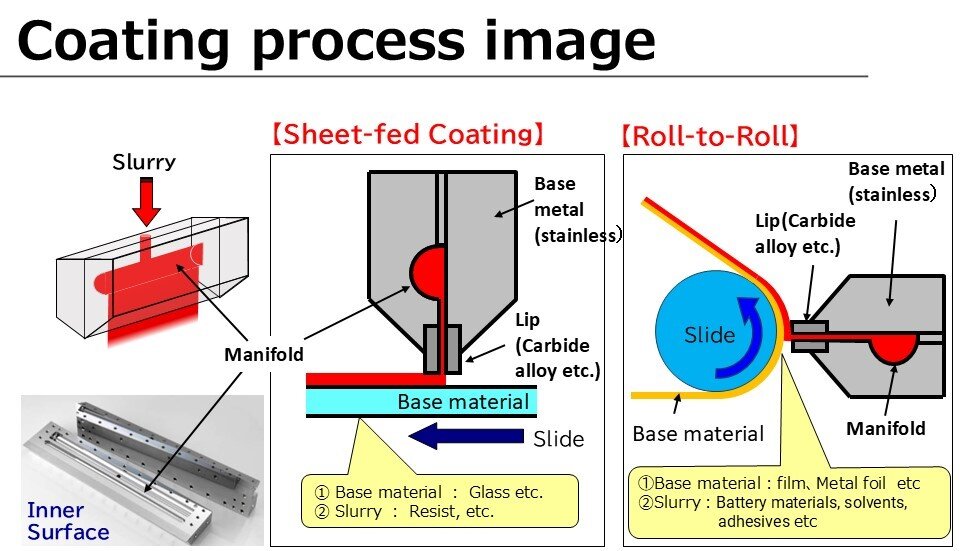

"Coating process" using printing technology

Market trends and expectations for practical application

In Japan, 2025 is being touted as the "first year of mass production," with companies beginning full-scale efforts to build mass production systems. Supported by the Ministry of Economy, Trade and Industry's revision of the Feed-in Tariff (FIT) system and support from the New Energy and Industrial Technology Development Organization (NEDO), they are expected to be used in exterior wall materials, window glass, electric vehicles (EVs), and more. Meanwhile, full-scale mass production is expected to begin in the global market in the late 2020s, with some forecasts predicting the market size will reach 2.4 trillion yen by 2040. Research and commercialization are accelerating in Europe, China, the United States, and elsewhere, intensifying global competition.

Several technical challenges remain before commercialization can begin, including ensuring durability and long-term stability, improving the precision of manufacturing equipment, and ensuring material safety. However, domestic and international universities, companies, and ventures are collaborating to begin demonstration tests and small-scale production. In addition to major companies, university-based ventures and chemical manufacturers are also entering the market, further accelerating the development race.

Several technical challenges remain before commercialization can begin, including ensuring durability and long-term stability, improving the precision of manufacturing equipment, and ensuring material safety. However, domestic and international universities, companies, and ventures are collaborating to begin demonstration tests and small-scale production. In addition to major companies, university-based ventures and chemical manufacturers are also entering the market, further accelerating the development race.

Coating process supported by Mitsubishi Materials Group technology

The "coating process" of film-forming ink is particularly critical in the manufacture of perovskite solar cells. The liquid material must be applied uniformly and with high precision, and the quality of this process directly impacts the performance of the solar cell. One coating tool attracting attention in this field is the "slot die" from Mitsubishi Materials Hardmetal Corporation (formerly MMC RYOTEC Corporation, which changed its name on July 1, 2025), a member of the Mitsubishi Materials Group.

Since its development over 40 years ago, slot dies have been applied in a variety of fields, including liquid crystal displays, organic light-emitting diodes (OLEDs), fuel cells, lithium-ion batteries, optical films, and capacitors. Technology continues to evolve to create uniform thin films from liquid materials, and Mitsubishi Materials Hardmetal's slot dies are uniquely customized for each application and the material characteristics. Today, they are a key factor in determining the performance of perovskite solar cells.

Moreover, Mitsubishi Materials and EneCoat Technologies Co., Ltd. (*) have jointly conducted research and development of an electron transport layer , a component of perovskite solar cells, and developed a coating-type ink for film deposition that achieves approximately 1.5 times higher power conversion efficiency than conventional inks. The Mitsubishi Materials Group will contribute to the widespread adoption of higher-performance perovskite solar cells by maximizing synergies not only with coating tools but also with its material and process technologies.

* EneCoat Technologies Co., Ltd.: Founded in January 2018, this Kyoto University-based startup specializes in the development of perovskite solar cells, which are attracting attention as next-generation solar cells. As the only company in Japan specializing in perovskite solar cells, it handles everything from material development to commercialization. We invested in EneCoat Technologies in May 2020 through the "MMC Innovation Investment Limited Partnership."

Since its development over 40 years ago, slot dies have been applied in a variety of fields, including liquid crystal displays, organic light-emitting diodes (OLEDs), fuel cells, lithium-ion batteries, optical films, and capacitors. Technology continues to evolve to create uniform thin films from liquid materials, and Mitsubishi Materials Hardmetal's slot dies are uniquely customized for each application and the material characteristics. Today, they are a key factor in determining the performance of perovskite solar cells.

Moreover, Mitsubishi Materials and EneCoat Technologies Co., Ltd. (*) have jointly conducted research and development of an electron transport layer , a component of perovskite solar cells, and developed a coating-type ink for film deposition that achieves approximately 1.5 times higher power conversion efficiency than conventional inks. The Mitsubishi Materials Group will contribute to the widespread adoption of higher-performance perovskite solar cells by maximizing synergies not only with coating tools but also with its material and process technologies.

* EneCoat Technologies Co., Ltd.: Founded in January 2018, this Kyoto University-based startup specializes in the development of perovskite solar cells, which are attracting attention as next-generation solar cells. As the only company in Japan specializing in perovskite solar cells, it handles everything from material development to commercialization. We invested in EneCoat Technologies in May 2020 through the "MMC Innovation Investment Limited Partnership."

Mitsubishi Materials Hardmetal's coating tool "Slot Die"

Mitsubishi Materials Hardmetal's coating tool "Slot Die" (Disassembly photos)

In our next issue, we will look into the challenges and aspirations of the engineers on the ground who support this technology, as well as the voices of users.